Donald Trump’s call for Netflix to remove board member Susan Rice has intensified the Paramount saga, pushing the streaming wars into a political confrontation.

The Rise of Agentic AI: How Autonomous AI is Transforming Manufacturing

Artificial intelligence is evolving beyond generative AI to a more autonomous and proactive form known as Agentic AI. Unlike traditional AI that requires user prompts, Agentic AI acts independently, making decisions and executing tasks without direct human intervention. This emerging technology is poised to revolutionize manufacturing, optimizing operations, reducing downtime, and improving efficiency.

What is Agentic AI?

Agentic AI is designed to analyze data in real-time, anticipate needs, and take autonomous actions without waiting for explicit instructions. This distinguishes it from generative AI, which focuses on creating content but lacks independent decision-making abilities.In manufacturing, where speed, precision, and efficiency are paramount, Agentic AI is proving to be a game-changer by seamlessly integrating into existing workflows and optimizing operations at scale.

Key Applications of Agentic AI in Manufacturing

Here’s how Agentic AI is reshaping the industry:

1. Process Optimization

Agentic AI continuously analyzes manufacturing processes, identifying inefficiencies and making real-time adjustments to improve performance. This leads to higher productivity, lower costs, and reduced waste.

2. Predictive Maintenance

One of the biggest challenges in manufacturing is unexpected equipment failure. Agentic AI monitors machinery in real-time, predicts potential breakdowns, and schedules maintenance autonomously, minimizing downtime and reducing maintenance costs.

3. Inventory Management

Instead of relying on static inventory systems, Agentic AI dynamically adjusts stock levels based on real-time demand and supply chain data. This ensures optimal inventory levels and eliminates unnecessary delays caused by stock shortages or overordering.

4. Quality Control & Defect Detection

By integrating with vision systems and sensors, Agentic AI can detect product defects in real-time and adjust production parameters autonomously. This results in higher-quality products and reduced waste from defective items.

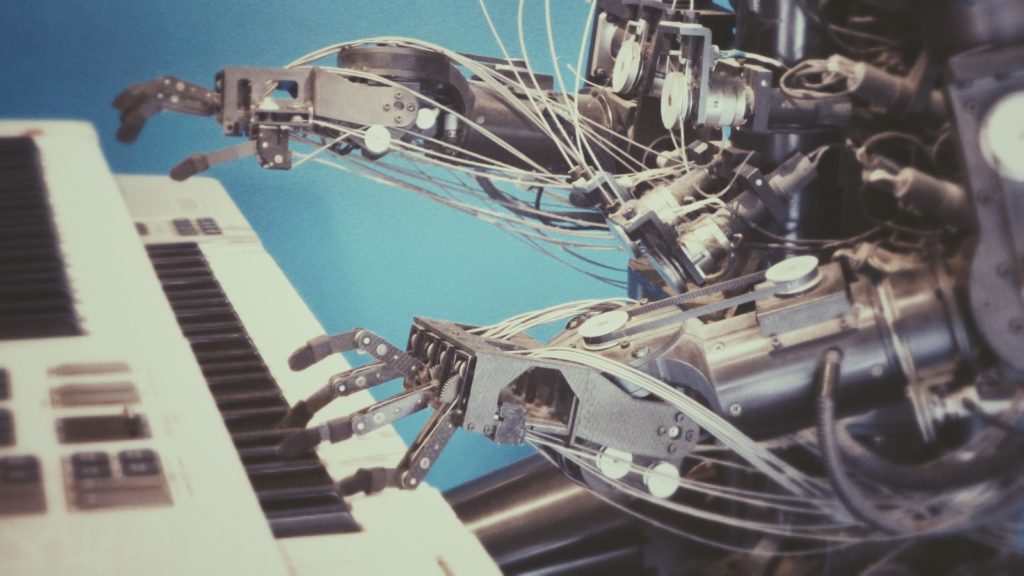

5. Robotic Assembly & Smart Automation

Agentic AI powers autonomous robots that can adapt to changes on the assembly line, making real-time decisions to optimize performance. Unlike generative AI, which may design robotic systems, Agentic AI directly controls robotic actions, enhancing flexibility and responsiveness in manufacturing environments.

Agentic AI vs. Generative AI: What’s the Difference?

While Generative AI has made waves with its ability to create text, images, and code, Agentic AI goes a step further by making decisions and executing actions without user prompts.

Here’s a quick comparison:

| Feature | Generative AI | Agentic AI |

|---|---|---|

| Decision-Making | No | Yes |

| Autonomous Actions | No | Yes |

| Use Case | Content Creation | Real-time Process Optimization |

| Manufacturing Role | Generates reports, designs products | Manages operations, controls machinery |

The Future of Manufacturing with Agentic AI

As manufacturers continue to seek greater efficiency and cost savings, Agentic AI adoption will accelerate. Businesses that integrate autonomous AI-powered solutions into their operations will gain a competitive edge, benefiting from improved productivity, reduced costs, and enhanced quality control.

Agentic AI represents the next frontier of artificial intelligence, with far-reaching implications for manufacturing and beyond. Its ability to make decisions, optimize processes, and enhance automation positions it as a critical technology for the future of industrial operations.

As companies explore AI-driven innovations, those leveraging Agentic AI will set new standards in efficiency, scalability, and intelligent automation. The future of manufacturing is here—and it’s autonomous.