With powerful hardware working together with an industry-leading camera system and intuitive AI experiences, everyday tasks have never been easier and faster

CATL could have the 1000km EV battery

CATL is the world’s most important battery manufacturer. The Chinese company dominates battery manufacturing, and its scale is such that any change in chemistry chosen by CATL engineers has industrial-scale consequences.

The Automotive industry is struggling to access a true battery technology breakthrough, with energy density and mass continuing to be an issue. Heavy cars are terribly inefficient and EVs are the heaviest vehicles in their class. The problem is quite obvious, because all that mass discrepancy is due to the battery pack.

To achieve the driving range customers have with internal combustion cars, manufacturers have no choice but to opt for heavy battery packs. These offer the theoretical range required, but their mass reduces overall efficiency.

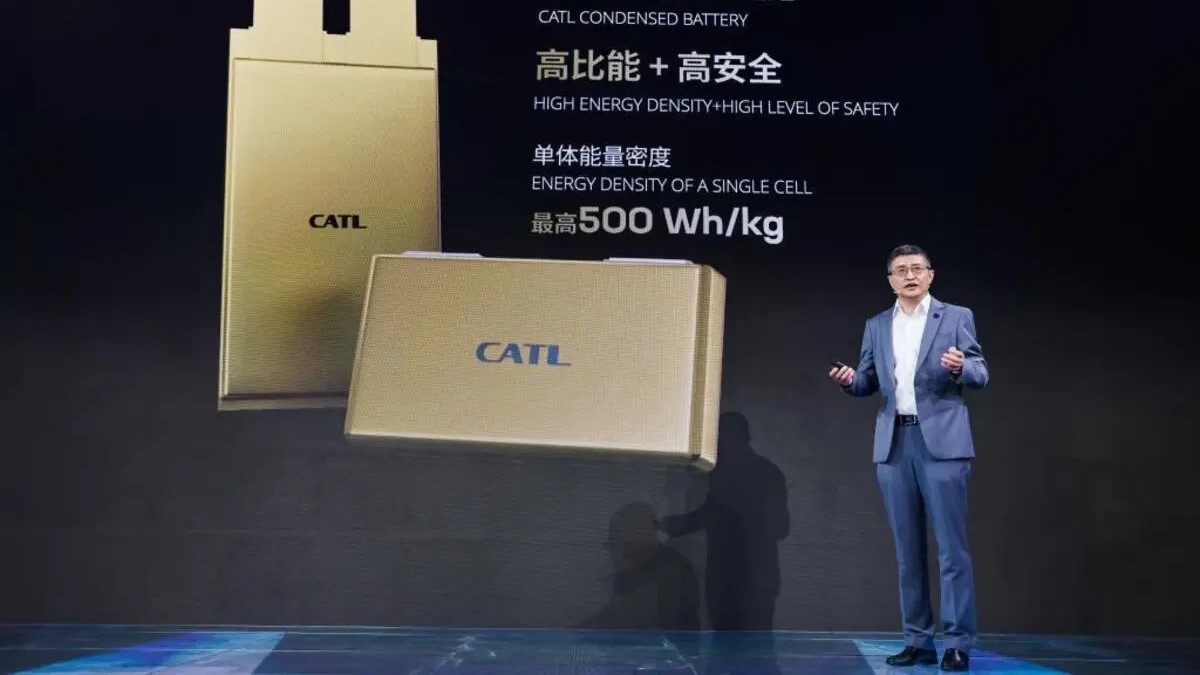

CATL condensed tech

In the paradoxical world of battery chemistry, CATL has announced a new battery pack that could make electric vehicles a lot more viable for more people. The design purpose is to power electrified flight, but the terrestrial vehicle application has immense theoretical potential, considering the claimed energy density.

These could become the first batteries to deliver true 1000km driving range, for EVs.

The new CATL condensed battery pack has a power density rating of 500Wh/kg. To contextualise that, Tesla’s best production battery pack technology is 296Wh/kg. The 500Wh/kg battery would allow viable driving range, with much smaller batteries. This would reduce overall EV vehicle weight without sacrificing driving range.

If these batteries are produced at scale, they could yield lighter and much more powerful EV power packs than a petrol or turbodiesel engine.

But how has CATL achieved such energy density? According to the company, it has used an ultra-high energy density cathode blended with advanced anode materials. But what is its chemistry? CATL’s technical documentation mentions Lithium but does not detail the actual battery chemistry.

The most sceptical question regards the elements used in this 500Wh/kg battery and whether they are rare earth minerals or not? As demand surges, there is a global rush to secure rare earth metal supplies for mining and battery manufacturers.

Some automotive battery experts have expressed a need for the industry to transition to different chemistries, less reliant on cobalt and other materials with a problematic sourcing profile.

CATL has promised that its new 500Wh/kg battery production should commence next year.