With youth unemployment above 60 percent, South Africa is betting on digital skills to drive inclusive growth. Here is how MICT SETA is positioning the next generation for the Fourth Industrial Revolution.

DIY cellphone from MIT is a labour of geek love

Mobile phones don’t have to be an ambitious devices bathed in the hottest tech. In this light, the Massachusetts Institute of Technology’s (MIT) Media Lab has created a DIY mobile phone, a US$150 device with a 1.8-inch colour screen. And it only makes voice calls. This is no joke, it’s a real initiative created by the boffins at MIT.

The post detailing the DIY mobile phone asks some fairly weighty questions for a handheld device.

How close can a homemade project come to the design of a cutting edge device? What are the economics of building a high-tech device in small quantities? Which parts are even available to individual consumers? What’s required for people to customize and build their own devices?

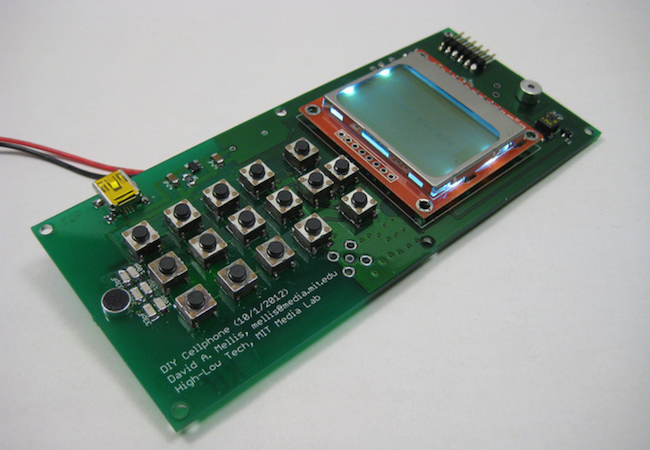

All excellent questions, which should be fully explored with the DIY phone. “Freed from the constraints of mass production, we plan to explore diverse materials, shapes, and functions.” This is key, and it’s something we discuss often at the Gear, how form factor is more important than internals these days. Because the specs for the DIY phone, even for a US$150 are pretty shoddy. The phone is a side project by David A. Mellis, a student at MIT who seems to be pretty keen on open-source technology.

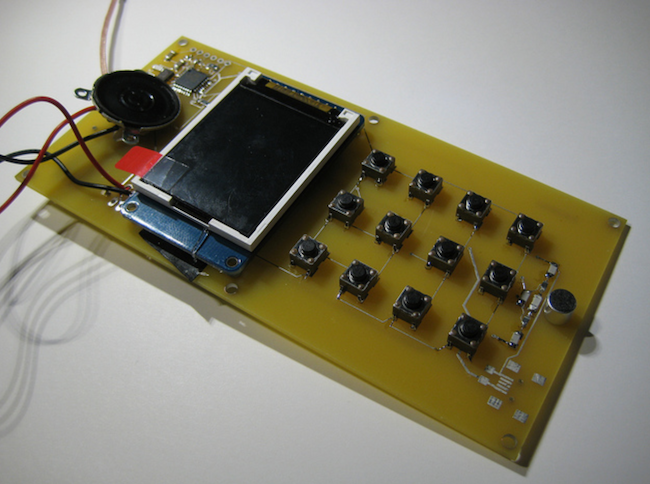

The 160×128 display is colour, 1.8-inches and TFT (think of the display on the old Alcatel’s). The functionality includes voice calls. That’s it for now, but by exploring the hardware which can be downloaded here it’s possible to expand on the features of the DIY mobile phone.

Did you click that link? That’s coding for the OS and circuit board diagrams. Perhaps now you realize how badly MIT wants you to create a phone from scratch. It’s the dream of any geek, to create a phone from raw materials. It won’t be easy though. The project is aimed at engineers; this is high-level tinkering with plenty of room for growth.

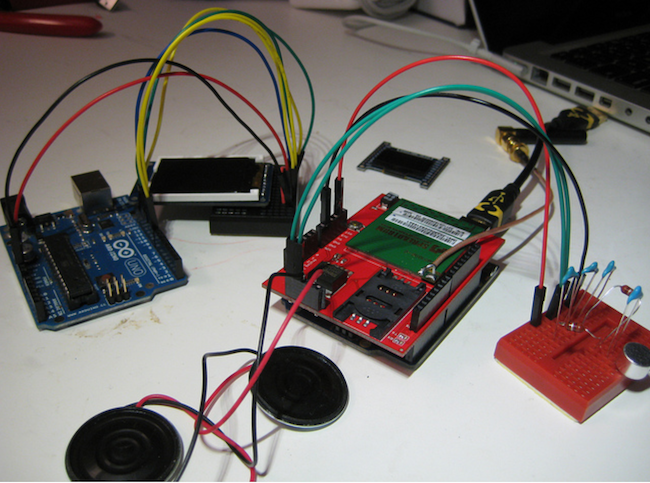

More importantly, how does the DIY mobile phone receive and place calls? With a US$60 GSM module, care of Sparkfun.com. This is combined into the circuit board and MIT says the module will accept “any standard SIM”. We looked at the SIM breakout board which usually ships with the GSM module, and it seems like it won’t handle micro or nano-SIM’s. Bit of a downer, but those SIM’s are usually reserved for smartphones, which the DIY phone is leagues from.

Prototyping

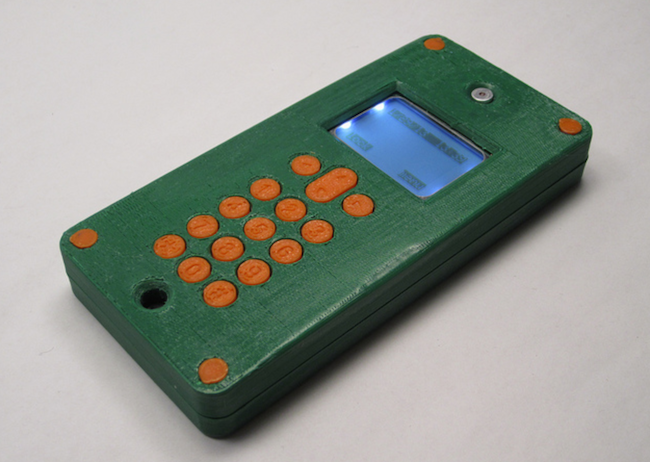

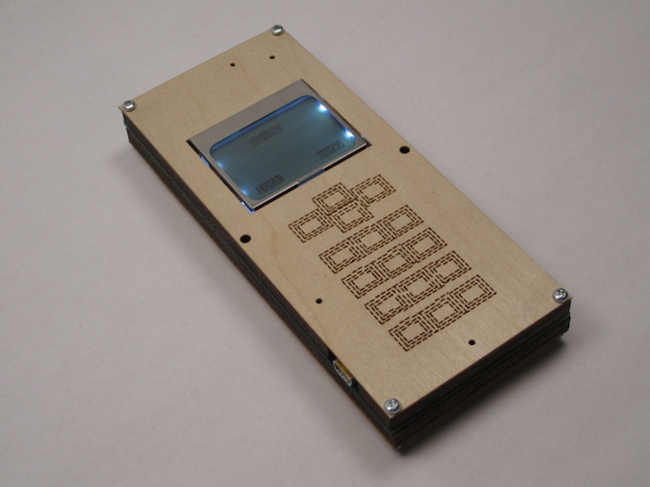

We’re very much in love with the look of this simple prototype phone which combines solid tinkering with a laser-cut plywood and a veneer enclosure. Here’s the full set of photos, from board to phone, but we’ve selected the best ones.

If the technology gets cheaper, the uses for the DIY phone will be endless. Even better, if the parts become “lego-like”, as in it arrives in a few pieces and is easy to assemble, it could very well be the most important emergent-market device. Here’s a scenario: the DIY phone is shipped with just two parts, the case and the circuit board. An assembly line then closes it up and the device is sold for under US$10. Countries can even save money by printing homemade cases, so to speak. Given time, Mellis’ creation may take over the entry-level mobile world.

Images via Flickr