Sony launches the WF-1000XM6 in South Africa with upgraded noise cancelling, better call clarity and premium sound. Pricing starts at R7,999.

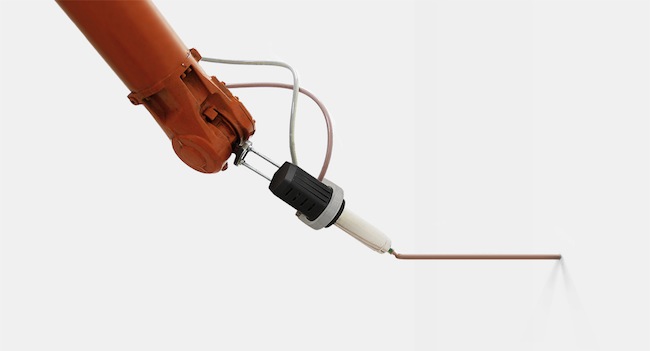

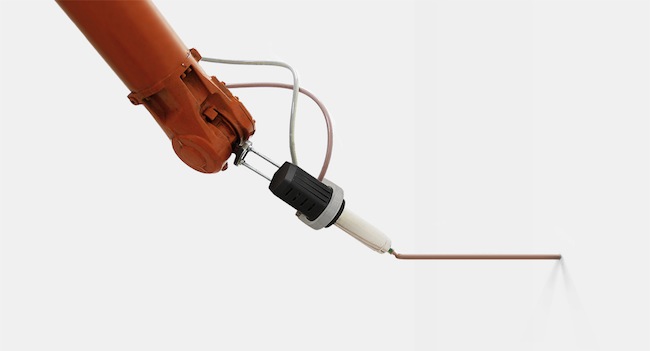

Meet Mataerial: the ‘anti-gravity’ 3D printer

3D printing from any surface, at any angle, without fail. While 3D printing has yet to become a household gadget, it’s far from reaching its creative zenith and Mataerial, a prototype 3D printer that can extrude shapes from any surface, creates new possibilities for an extremely young medium.

Saša Jokić and Petr Novikov (from the Spain-based Institute for advanced architecture of Catalonia), together with the Joris Laarman Studio, have developed a printing arm called Mataerial that can form surfaces and objects without support material. Standard 3D printers use sandwiched 2D layers to create a three-dimensional form. What Mataerial does is combine 3D curves for “more control over the fabrication process.” It’s just a prototype, so there’s no mention of price, but this beast looks exceedingly industrial, so it’ll be priced far outside of the reach of normal gadget lovers. Its powers are neatly demonstrated in the video below.

The results are some incredible looking 3D-printed tubes. Mataerials’s makers describe this as “anti-gravity object modeling,” which the official site has much to say about:

Conventional methods of additive manufacturing have been affected both by gravity and printing environment: creation of 3D objects on irregular, or non-horizontal surfaces has so far been treated as impossible. By using innovative extrusion technology we are now able to neutralize the effect of gravity during the course of the printing process. This method gives us a flexibility to create truly natural objects by making 3D curves instead of 2D layers. Unlike 2D layers that are ignorant to the structure of the object, the 3D curves can follow exact stress lines of a custom shape.

We’d love to see more creative shapes, outside of tubes but Mataerial does account for full colour printing as a coloured dye is injected into the 3D shape during the printing process. Mataerial’s developers won’t reveal which thermoset polymers are combined to form the printed material, so it’ll be hard to tell if the machine can be used to form two-minute noodles.