With stablecoins gaining traction and regulation improving, African merchants may be nearing a crypto tipping point. Here’s why 2026 could mark a shift from hesitation to adoption.

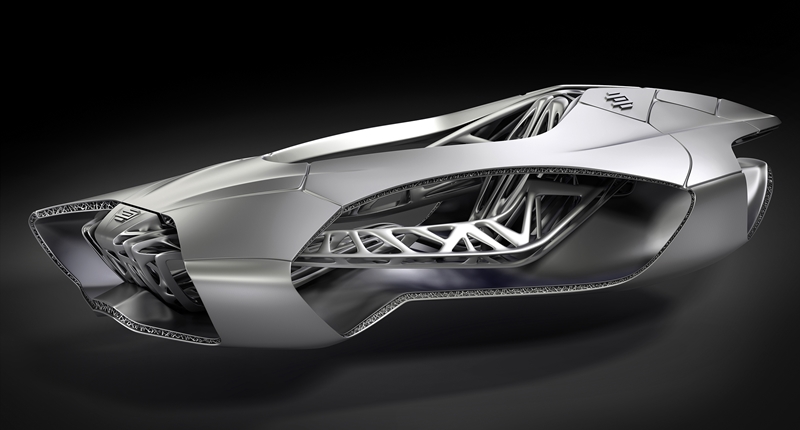

Take a look at what happens when car designers get extreme with a 3D printer

This is undoubtedly one of the coolest uses of 3D printing we’ve seen to date. German design and engineering firm EDAG has produced a 3D printed concept of what car bodies might look like in the future.

Called “Genesis”, the passenger shell is inspired by the body of a turtle and is apparently tool-free, resource-saving and eco-friendly. We can see that. It almost looks organic and if it can skip a few stages of today’s complex assembly lines, then it could certainly help save on energy and production costs.

According to EDAG, Genesis’ skeleton is “more of a metaphor; it is there to ensure not mobility, but passenger safety”. It adds that the potential behind the kind of manufacturing put into Genesis should also help to reduce the weight of the plant technology, leading to energy savings in its production and operation: the tendency is towards lighter components, lighter tools, lighter clamping technology, smaller robots.

Untangling EDAG’s engineering-jargon heavy press release, it’s pretty clear that putting this kind of shell into production isn’t really viable right now.

That said, the company reckons it’s not all that far away and that small structural parts could start appearing in production cars even sooner.