With stablecoins gaining traction and regulation improving, African merchants may be nearing a crypto tipping point. Here’s why 2026 could mark a shift from hesitation to adoption.

The drive to perfection: a brief evolution of vehicle transmissions

If there has been one area of car development that’s undergone a massive tech explosion over the years, it’s transmissions. Facing more recent pressure from lawmakers, the environment and the public than ever before, the past decade has seen automakers move away from fuel-drunk Earth-killers and towards smarter, greener and cleaner vehicles.

Most are developing a form of hybrid power unit, meshing combustion engines with rechargeable electrical motors. Others like BMW, have invested heavily in lighter construction materials, shunning traditional alloys in favour of “carbon fibre and thermoplastic,” in the case of its i8. But those not ready to completely abandon hope in petroleum are developing smarter drive trains and more efficient transmissions for current generation vehicles, increasing engine efficiency.

Even motorsport series like Formula 1 and the World Endurance Championship has seen rule changes embracing new transmission technologies. After all, a vehicle’s transmission ensures that all the engine’s puff arrives at the wheels as effectively as possible.

Brief history lecture

The concept of the cog has been under constant development since the Greek’s inadvertent invention of the mechanical gear nearly two millenniums ago. Perhaps James Watt’s (coincidentally, the brains behind the concept of horsepower too) invention of the planetary gear system, paired with 1700s steam engines, paved the way for further industrial and automotive applications. One has to wonder what he’d think of the current technology whirling around today.

A car’s transmission sends rotational energy produced by the engine to the wheels as efficiently and smoothly as possible. A driveshaft is rotated on the engine-side, while the gearbox connects it to the output shaft. Gears are selected based on the vehicle’s speed, engine revs and demand for de- or acceleration. The larger initial gears drive smaller ones, providing a large mechanical advantage and acceleration. Theoretically the more gears a transmission has, the easier it is for an engine to remain within its power band and at its most efficient RPM. All transmissions are different in implementation but fundamentally, they all transfer energy from the power source to the output mechanism – which is, in a vehicle’s case, the wheels.

This great video from Automotive Basics describes the process more comprehensively.

Multi-geared systems

To condense history into a brief article I’ll focus on a few major transmission breakthroughs. The dawn of the motor car changed the way people moved around in the 19th century. Gottlieb Daimler saw the advantage of multi-geared systems in his vehicles, with his “horseless carriage” in 1886. Although not completely gear-driven, his system was no-less influential.

“Depending on the chosen ratio the engine’s belt pulley drove discs of different sizes on a lay shaft. The power was transferred to gears on the rear wheels via pinions on both sides. Instead of a differential a slip clutch was mounted on each side of the lay shaft.”

Later, his 1889Â Stahlradwagen would feature a four-speed transmission driven exclusively by gears, co-developed by Wilhelm Maybach. Back then, this development we take for granted now was a world first.

Vehicle transmission systems underwent another transformation in the 1920s. Cadillac developed the first synchromesh gearbox – a system of constantly synchronised toothed gears. This negated the need for drivers to “double de-clutch“, which involved depressing the clutch, shifting to neutral, matching engine input speed with output speed manually syncing the gear’s teeth, before depressing the clutch once more to select the following gear. Who knew driving could be so difficult?

The helical synchromesh came later, allowing smoother shifts and smoother drive thanks to the constant contact the helical cogs provided. Modern gearbox cogs still employ this helical shape.

Automatic transmissions

But manual shifters were largely hated for the extra work it gave the driver. Enter the automatic transmission dubbed the “Hydra-Matic” developed by General Motors for the Oldsmobile. This was the world’s first mass produced automatic vehicle transmission at the time.

http://youtu.be/Ue07DdPQv0k

This development was about as revolutionary as the wheel itself and changed people’s perception of driving. Gone were the treacherous and laborious gear changes while climbing hills or descending into steep valleys. The gearbox controlled everything, allowing the driver the luxury of sitting back and steering.

Of course, modern vehicles takes this further by introducing sensor-assisted cruise control and other creature comforts.

Other novel ideas

Marques have never taken these inventions as gospel though, constantly striving for the next great invention.

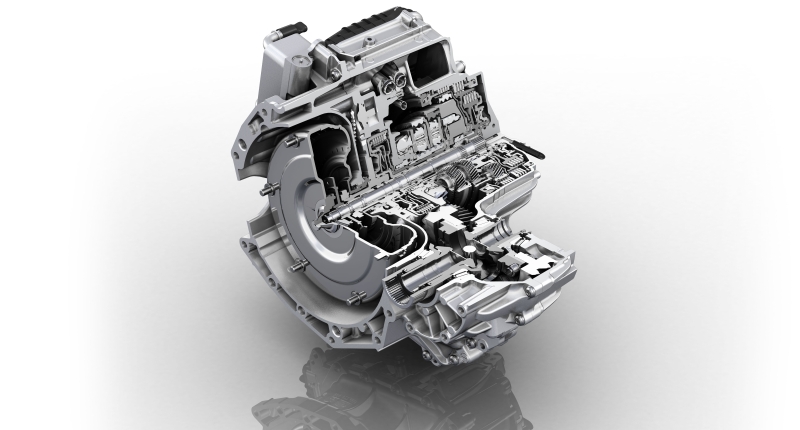

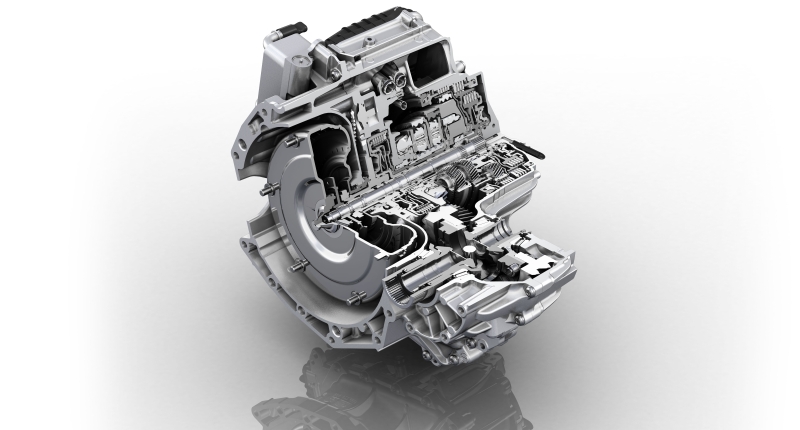

For example, Volkswagen developed its DSG gearbox for roadcars, which essentially uses two different gearboxes — one housing odd gears, the other even — and two clutches. The next gear was preselected and allowed for faster shifts and a more stable power delivery through gear changes. Previously, this technology was only prevalent in motor racing, but in 2003, the Golf R32 became the first production car fitted with a DSG or dual-clutch transmission.

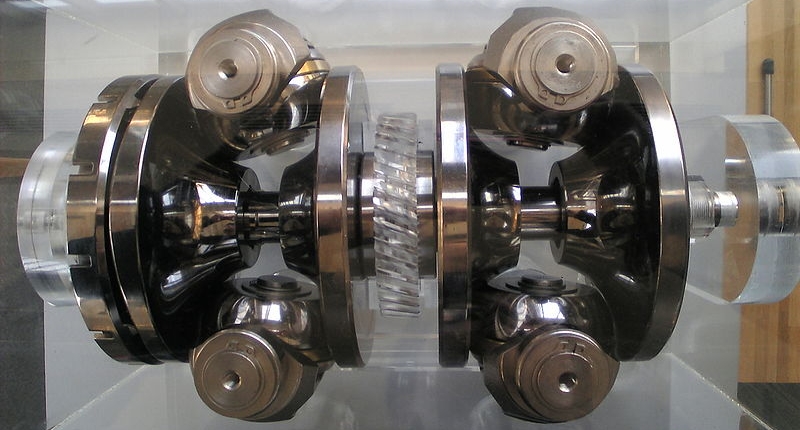

Prior to this though saw marques experiment with CVTs or continuously variable transmissions. The first to patent the technology was the Reeves brothers back in the late 1800s. It was first designed for agricultural machinery.

Although they’re terribly inefficient, CVTs (as its name suggests) provides a continuously variable set of ratios that adjust based on engine speed, negating the need for a multitudinous arrays of cogs. It allows for cheaper construction thanks to its simple design. Currently Nissan implements the system in a number of their models, their system is pictured above.

Transmissions of the future

Although there are many technologies both past and present, what does the future hold for transmissions?

A few weeks ago, Volkswagen has announced plans to implement their ten-speed DSG transmission in their upcoming models, from the insane Golf R400 to its off-road utility vehicles like the Touareg.

Ten speeds seems incredibly unnecessary seeing that Chrysler and ZF developed a 9-speed gearbox a few years ago. According to the ZF VPÂ Michael Paul’s comments from a few months ago, he actually suggested that ten-speeds would probably never see the light of day.

Of course, more cogs only currently benefit vehicles at cruising speeds. When coupled to an intelligent cruise control system for analysing traffic flow or an electric motor that generates electricity from the engine’s motion, there may be an advantage yet to be unlocked.

Modern CVT’s may also completely replace multi-cogged gearboxes too, with manual transmissions slowly dying out. As fuel efficiency demands and carbon emission laws increase, automakers will likely fit vehicles with automatic gearboxes, ensuring that the car’s brains, not the driver’s heavy foot, does the driving.

BMW though, believes that its formula of eight-speed automatics, seven-speed dual clutch gearboxes and six speed manuals is in the best interests of car and driver.

If this is the case, we could face the death of driving as an enjoyable past time and petroleum-powered supercars too. The world will be healthier, yet all the sadder for it.