MTN South Africa has once again emerged as the country’s top-performing mobile network, securing the highest score in the Q2 2025 MyBroadband Network Quality…

Fujitsu explores the possibility of liquid-cooled smartphones

We’ve all experienced heat emanating from our cellphones when held against our ears too long and that warm, tingling sensation from laptops when resting against our laps, or as Homer Simpson would say, “mmm… erotic radiation.”

While liquid-cooled PCs have been around, the smaller size of smartphones, laptops and tablets require more traditional methods of cooling, relying mostly on sheets of metal or other materials that conduct heat away from key components and chips to prevent damage.

In fact, finding newer ways to cool these smaller devices is key if we are to see continued innovation in the portable device market. Fujitsu to the rescue.

Introducing Fujitsu’s loop heat pipe

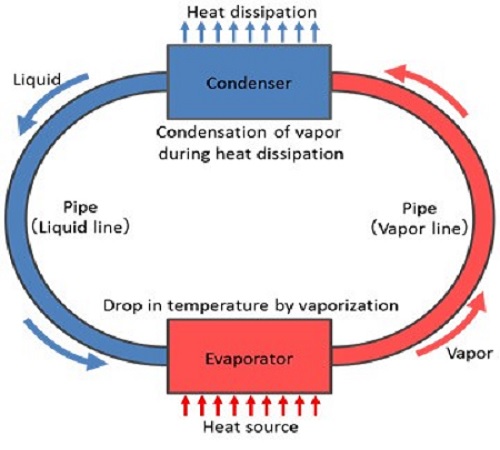

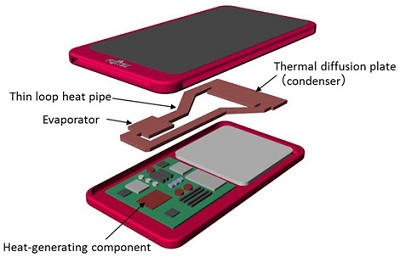

Engineers at Fujitsu Laboratories in Kawasaki, Japan, are developing a thin, loop-shaped heat pipe made out of copper that is filled with water. This new device consists of a loop that connects two pieces, an evaporator which sits above the hottest part of any portable device, the CPU, and a condenser located near cooler parts.

More specifically, the evaporated water is funneled through a vapor line that condenses when making contact with the loop’s thermal diffusion plate. Finally, the condensed water flows through a liquid line back to the evaporator.

According to Takeshi Shioga, a researcher at Fujitsu Laboratory’s Product & Systems Engineering Laboratories, “the capillary action enables the liquid to easily circulate and readily transfer heat no matter how the device is positioned.”

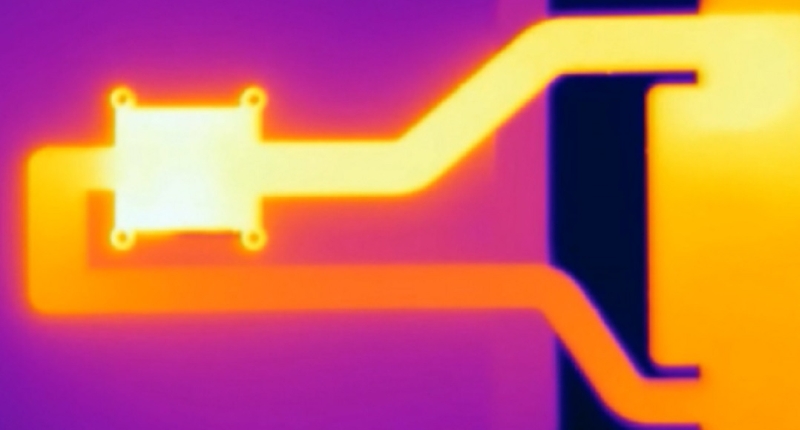

The pipe and evaporator sections are also the world’s thinnest at 0.6 millimeters thick.

Fujitsu hopes to implement this design in devices sometime in 2017, and explore the possibility of inclusion in other systems and devices like communication infrastructure, medical equipment, and small notebook computers.

Article originally published on TechGenMag. Republished with permission from Kristian Markus, TechGenMag Editor.