Inbox icons, subject line sorcerers, CTA kings – the results are in. The 2025 You Mailed It Awards by Everlytic have crowned their champs, with Old Mutual Rewards and Machine_ taking…

Driving change: is 3D printing transport’s biggest disrupter?

Transportation is probably the most interesting industries to witness undergoing change. A century-old invention seems like it’s finally on the cusp of changing the way we go from point A to B. From the internet and GPS to 3D printing, Driving Change is a four-part series that covers the most powerful technologies moulding 21st century transport as we know it.

A lot of things can be 3D printed these days. By using a variety of materials such as plastic, metal, stem cells and even human tissue, complex parts such as replacement joints, consumer clothing and engine parts can be created in your bedroom.

In Amsterdam, a company has designed a robotic 3D printer that’s planning to build a bridge over one of the city’s canals. While it’s helping people overcome difficult terrain, other 3D printing companies are creating actual cars to do so in style.

The technology could affect nearly all aspects of transportation. First and foremost, 3D printing could reshape logistics — an industry which accounts for a massive part of the world’s transportation.

On a micro level, keeping your car intact could also be easier as spare parts become more accessible and cheaper.

Logistics

A report by PwC estimates that 41% of air cargo and 37% of ocean container shipments are threatened by 3D printing.

Similar to how the printing press has revolutionised paper-based distribution around the year 1440, and the Industrial Revolution’s assembly line. But as great as these innovations were, they’re still limiting the products we see today.

A report by IBM notes that even after centuries of refinement, traditional manufacturing is defined, in part, by trade-offs. It goes on to explain that costs, complexity, packaging and the transportation of goods often don’t enable a product to leave the “design room” stage.

Read more: Driving Change: how self-driving cars could revolutionise our world

For a large part, products are shaped based on the limitations imposed by logistics. 3D printing could change this. The report by IBM sums it up nicely:

As production can take place closer to demand or even in-home, significant chunks of the current supply chain and related transportation needs become irrelevant.

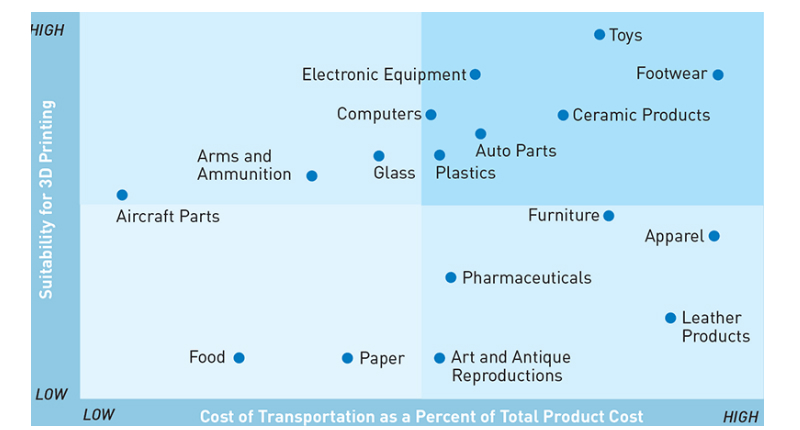

The graphic below by PwC shows which type of products are most and least suitable for 3D printing.

The graph shows auto parts are just below toys, footwear and ceramics. This suggests that not only could transportation of the logistics sector be disrupted by 3D printing, repairing and replacing vehicles could become a lot easier. So while there will be fewer trucks on the road, for example, those that are there could be maintained at a fraction of the cost we know today.

Repairs and product development

Just last month, Motorburn wrote about Blade (pictured above). The supercar’s whole chassis was 3D printed.

Local Motors from the US furthermore printed a crowdsourced-designed car. Whereas typical cars have tens of thousands of parts, the Strati has fewer than 50.

These initiatives are part of a bigger story that would one day tell of people buying fan belts printed down the road or in their own garages. This isn’t all bad news for auto manufacturers.

Read more: Driving Change: how data is making our cities move smarter

In a report by Ford, the US auto manufacturer noted how 3D printing saves the company millions of dollars in the product development process by eliminating the need for special tooling.

One day, Ford notes, millions of car parts could be printed as quickly as newspapers and as easily as pushing a button on the office copy machine, saving time and money. In fact, some estimate that the use of 3D printing in the auto industry is set to quintuple over the next five years to a value of US$1.25-billion.

3D printing will push manufacturers to focus on producing highly technical products. Cheaper ones will be manufactured by 3D printing shops or individuals who can just download a file from a website.

Driving Change is a series brought to you by Driverly — a service which aims to make driving smarter by connecting and rating driving instructors with learners. Founded by Chad Williams in 2015, Driverly aims to create a smart and structured learning experience for all learner drivers, presented by highly skilled, licensed and highly rated driving instructors.

Driving Change is a series brought to you by Driverly — a service which aims to make driving smarter by connecting and rating driving instructors with learners. Founded by Chad Williams in 2015, Driverly aims to create a smart and structured learning experience for all learner drivers, presented by highly skilled, licensed and highly rated driving instructors.